Introduction to 3D Printing

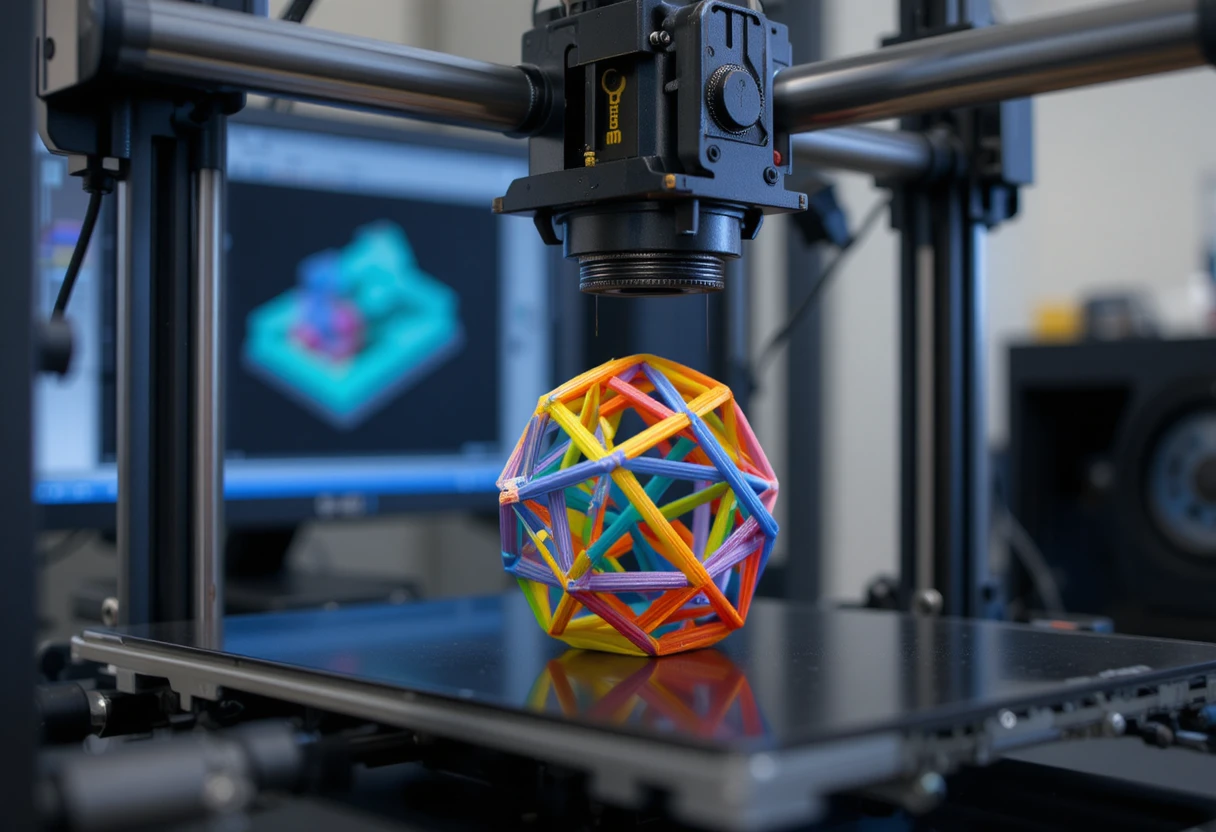

3D printing, also known as additive manufacturing, is a transformative technology that allows the creation of three-dimensional objects from digital files. Unlike traditional manufacturing methods that often involve subtracting material from a larger block or molding materials into shapes, 3D printing builds objects layer by layer. This process begins with a digital model, typically created using computer-aided design (CAD) software, which is then sliced into thin horizontal layers. The printer interprets these slices and deposits material accordingly, fusing each layer to the one below it until the final object is complete.

The appeal of 3D printing lies in its versatility and accessibility. What started as a niche tool for engineers and designers has now permeated various industries and even hobbyist communities. With desktop 3D printers available for under $200, individuals can prototype ideas at home, customize products, or even produce functional parts. This democratization of manufacturing has sparked innovation, enabling rapid prototyping and reducing the time from concept to product. Moreover, 3D printing minimizes waste by using only the necessary amount of material, making it an environmentally friendlier option compared to subtractive methods.

In essence, 3D printing bridges the gap between the digital and physical worlds. It empowers creators to iterate designs quickly, test functionalities, and produce complex geometries that would be impossible or cost-prohibitive with conventional techniques. As we delve deeper into this topic, we’ll explore its history, mechanics, applications, and future potential.

History of 3D Printing

The roots of 3D printing trace back to the 1980s, a period marked by rapid advancements in computer technology and materials science. The first patent for a 3D printing process was filed in 1984 by Chuck Hull, who is widely regarded as the inventor of stereolithography (SLA). Hull’s invention used ultraviolet light to cure layers of photopolymer resin, solidifying them into precise shapes. This breakthrough laid the foundation for what would become a multi-billion-dollar industry. By 1986, Hull founded 3D Systems, the first company dedicated to commercializing 3D printing technology.

Throughout the 1990s, other techniques emerged, expanding the capabilities of additive manufacturing. Selective laser sintering (SLS), developed by Carl Deckard at the University of Texas, used a laser to fuse powdered materials like nylon or metals. Fused deposition modeling (FDM), patented by Scott Crump in 1989, involved extruding thermoplastic filaments through a heated nozzle—a method that remains popular in consumer-grade printers today. These innovations shifted 3D printing from a conceptual tool to a practical one, initially adopted by aerospace and automotive sectors for prototyping.

The turn of the millennium brought open-source initiatives that accelerated adoption. In 2005, Dr. Adrian Bowyer launched the RepRap project, aiming to create a self-replicating 3D printer. This open-source movement made designs freely available, fostering a global community of makers. By 2009, patents on FDM expired, leading to an explosion of affordable printers from companies like MakerBot and Ultimaker. The 2010s saw 3D printing enter mainstream consciousness, with applications in medicine, such as printing prosthetics, and even space exploration, where NASA tested 3D-printed rocket parts.

Today, 3D printing has evolved into bioprinting tissues and organs, large-scale construction, and sustainable manufacturing. Its history reflects a journey from expensive industrial machines to ubiquitous tools, driven by innovation and collaboration.

How 3D Printing Works

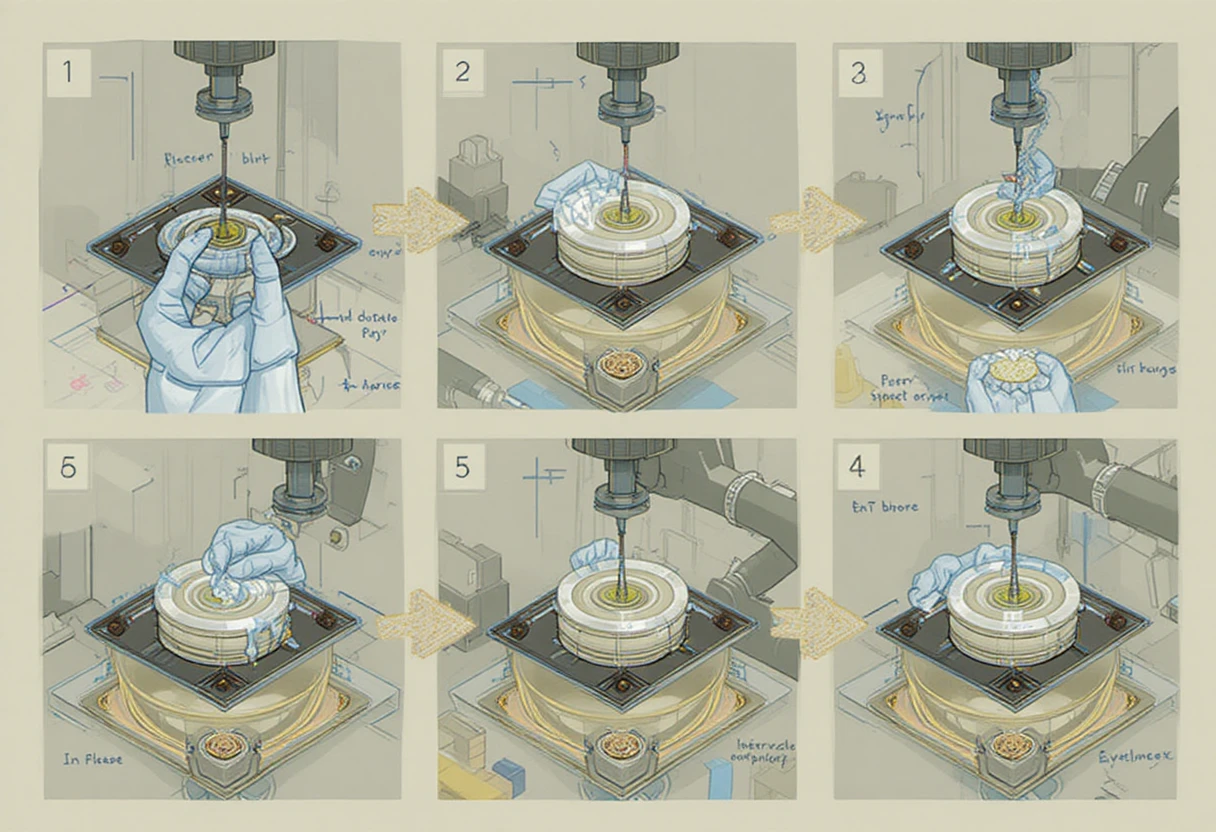

At its core, 3D printing follows a straightforward workflow: design, preparation, printing, and post-processing. The process starts with creating or obtaining a 3D model using software like Blender, AutoCAD, or Tinkercad. These models are saved in formats such as STL or OBJ, which represent the object’s geometry as a mesh of triangles.

Next, slicing software like Cura or PrusaSlicer divides the model into layers, generating G-code instructions that guide the printer’s movements. This code dictates parameters like speed, temperature, and layer height. The printer then executes the build, adding material incrementally.

Post-processing may involve removing support structures, sanding surfaces, or applying finishes for aesthetics and durability. Understanding this workflow is crucial for optimizing prints and troubleshooting issues like warping or layer adhesion.

Types of 3D Printing Technologies

Several technologies dominate the 3D printing landscape, each suited to specific materials and applications.

Stereolithography (SLA) uses a laser to cure liquid resin, producing high-resolution parts ideal for jewelry and dental models. Its precision comes at the cost of post-curing and resin handling.

Fused Deposition Modeling (FDM) extrudes melted filament, building objects affordably. It’s beginner-friendly but limited in resolution compared to resin-based methods.

Selective Laser Sintering (SLS) fuses powder with a laser, enabling strong, functional parts from nylons or metals without supports. It’s used in industrial settings for its durability.

Digital Light Processing (DLP) is similar to SLA but uses a projector for faster curing, making it efficient for batch production.

Binder Jetting deposits a binding agent onto powder layers, versatile for metals and ceramics, often requiring sintering.

Directed Energy Deposition (DED) melts metal wire or powder with a laser, suitable for repairing large components in aerospace.

Each technology has trade-offs in speed, cost, and material compatibility, influencing their adoption across sectors.

Materials Used in 3D Printing

The choice of material is pivotal in 3D printing, determining the object’s strength, flexibility, and finish. Plastics like PLA (polylactic acid), derived from renewable resources, are popular for their ease of use and biodegradability. ABS (acrylonitrile butadiene styrene) offers durability and heat resistance, though it requires a heated enclosure to prevent warping.

Advanced filaments include PETG for impact resistance and TPU for flexibility, enabling prints like phone cases or gaskets. Composite materials, infused with carbon fiber or wood, enhance strength or aesthetics.

Metals such as titanium, aluminum, and stainless steel are printed via SLS or DED, producing parts for high-stress environments. Ceramics and glass are emerging, used in aerospace for heat-resistant components.

Bioprinting employs hydrogels and bio-inks containing living cells, paving the way for tissue engineering. Sustainable options like recycled plastics and bio-based resins are gaining traction, addressing environmental concerns.

Material science continues to innovate, with conductive filaments for electronics and shape-memory polymers for smart devices.

Applications of 3D Printing

3D printing’s versatility has led to widespread applications, revolutionizing industries by enabling customization and efficiency.

In Medicine

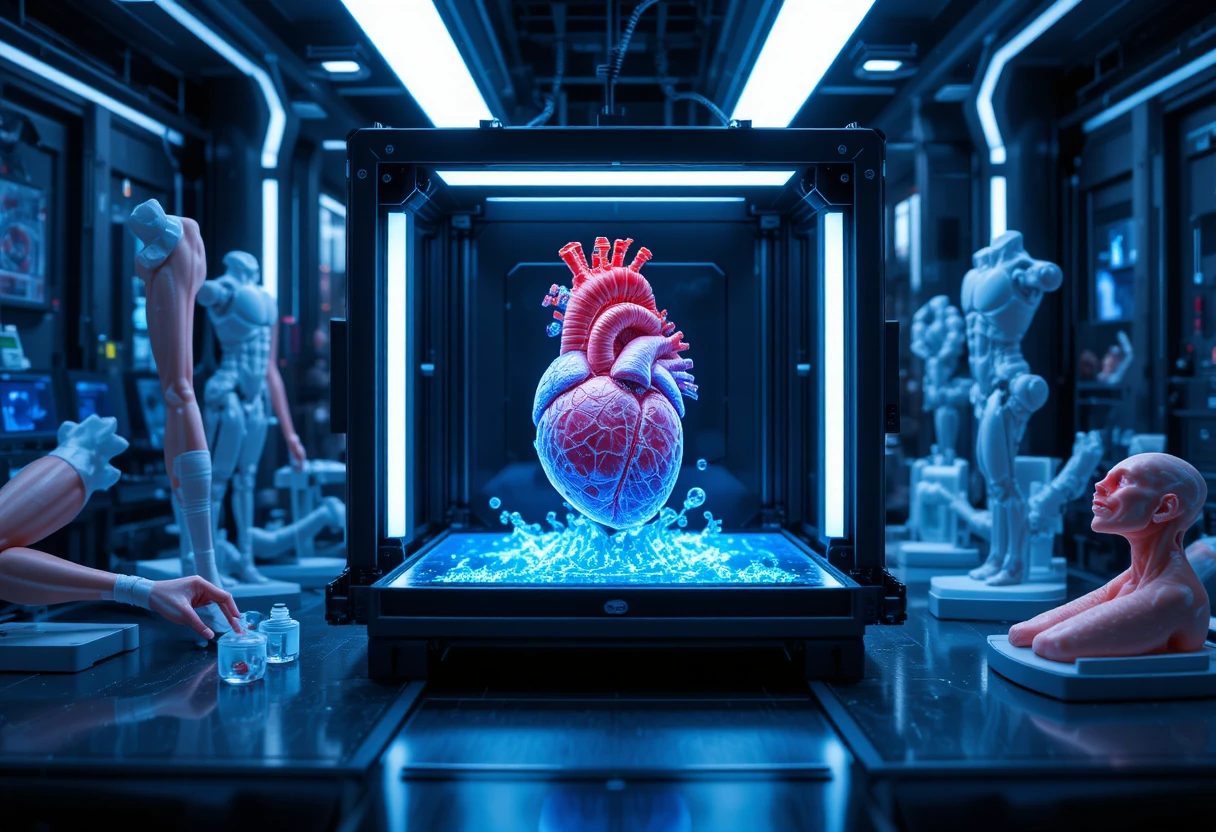

In healthcare, 3D printing creates patient-specific prosthetics, reducing costs and improving fit. Surgeons use printed models for pre-operative planning, enhancing outcomes in complex procedures.

Bioprinting is a frontier, with researchers printing skin grafts, blood vessels, and even organs like kidneys. During the COVID-19 pandemic, 3D printing produced ventilator parts and PPE rapidly.

Hearing aids and dental aligners are now routinely 3D-printed, offering precision and speed.

In Aerospace

Aerospace benefits from lightweight, complex parts. Companies like SpaceX and Boeing print rocket engines and turbine blades, reducing weight and assembly time.

NASA’s use of 3D printing on the ISS demonstrates its potential for on-demand manufacturing in space, minimizing resupply needs.

In Automotive

Automakers prototype components quickly, accelerating design cycles. Electric vehicle batteries and custom interiors are printed, with Bugatti using titanium parts for hypercars.

Mass customization allows for personalized vehicles, from dashboards to spare parts.

In Fashion and Consumer Goods

Fashion designers print intricate jewelry and clothing, like Iris van Herpen’s dresses. Consumer products include customized eyewear and footwear, with Adidas’ 3D-printed soles.

Home goods, toys, and art pieces are also produced, fostering a maker economy.

Advantages and Disadvantages

3D printing offers numerous advantages. It enables rapid prototyping, cutting development time from weeks to hours. Customization is effortless, ideal for one-off productions without tooling costs. Waste reduction promotes sustainability, and complex designs like internal lattices are achievable.

However, challenges persist. Print times can be lengthy for large objects, and material costs vary. Resolution limitations in some technologies affect surface quality, requiring post-processing. Intellectual property concerns arise with easy replication, and regulatory hurdles slow adoption in critical fields like medicine.

Scalability for mass production remains an issue, though hybrid approaches are emerging.

Future of 3D Printing

The future of 3D printing is bright, with advancements in speed, materials, and integration with AI. Multi-material printing will allow functional assemblies in one go, while 4D printing—objects that change shape over time—promises smart applications.

Sustainability will drive bio-based and recyclable materials. In construction, companies like ICON print homes affordably, addressing housing shortages.

Space colonization could rely on 3D printing habitats using local regolith. Bioprinting may solve organ shortages, with clinical trials underway.

Integration with robotics and IoT will automate production, ushering in Industry 4.0.

Conclusion

3D printing has evolved from a novel concept to a cornerstone of modern manufacturing. Its ability to innovate across fields underscores its potential to reshape our world. As technology advances, barriers will diminish, making it even more accessible. Whether for hobbyists or industries, 3D printing invites creativity and problem-solving, promising a future where imagination is the only limit.